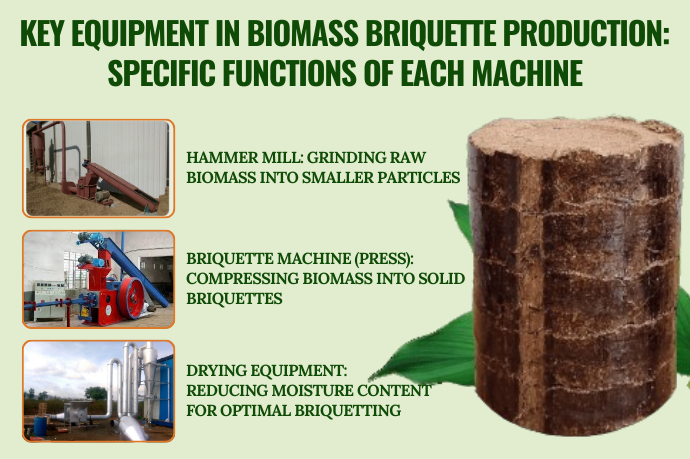

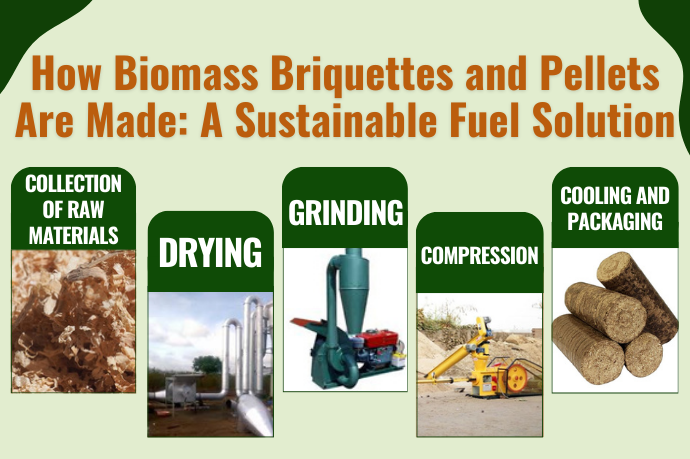

The production of biomass briquettes requires a well-coordinated process with different machines performing specific tasks to transform raw biomass into a high-quality, compact fuel source. Below is a breakdown of what each machine does specifically in the biomass briquette production process:

1. Hammer Mill: The hammer mill is used to grind large biomass materials, such as wood chips, sawdust, or agricultural waste, into smaller, uniform particles. It works by using rotating hammers to smash and reduce the size of the biomass, preparing it for the next stage of the briquette production process. This ensures that the raw material is fine enough for efficient compression during briquetting.

2. Briquette Machine (Press): The briquette machine compresses the ground biomass into solid, uniform briquettes by applying high mechanical or hydraulic pressure. As the biomass is pushed into molds, friction generates heat, which helps bind the particles together. This process forms dense, durable briquettes that can be used as an efficient fuel source.

3. Drying Equipment: Drying equipment, such as drum or rotary dryers, removes excess moisture from the biomass material. This is done by tumbling the biomass in a heated environment, ensuring the moisture content is reduced to the optimal level (10–15%). Proper drying ensures that the biomass can be efficiently compressed into strong, high-quality briquettes.

4. Cooling System: After the briquettes are compressed, they are hot and soft. The cooling system works by lowering the temperature of the briquettes using air, solidifying them and ensuring they harden properly. This cooling process helps maintain the briquettes' shape and durability during handling, storage, and transportation.

Conclusion:

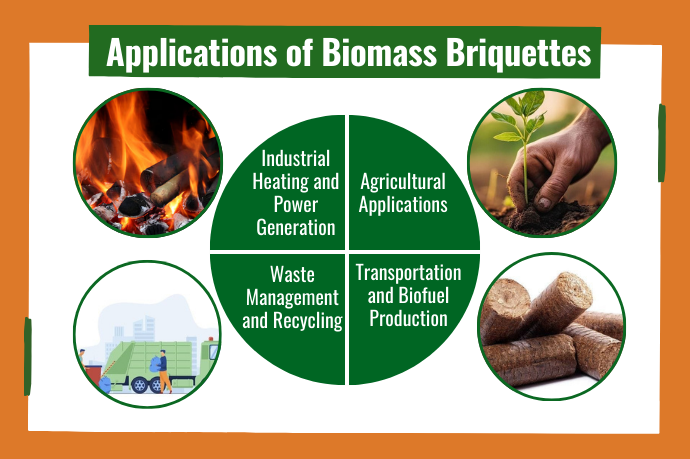

From the hammer mill that grinds raw material to the briquette press that compacts it, and the drying equipment that removes excess moisture, each machine is essential in producing a product that can be used as a sustainable energy source.

The cooling system ensures the briquettes are solid and durable, By understanding the function and importance of each of these machines, biomass briquette producers can optimize their production lines, reduce waste, and create a superior product that helps in reducing dependence on non-renewable energy sources.

As the demand for clean, renewable energy solutions continues to grow, the role of efficient biomass briquette production will be crucial in helping to meet global energy needs while supporting environmental sustainability.